In case of fibre optic high bitrate transmissions the purity of optical interfaces along the whole optical link is essential to provide a reliable optical transmission performance. When the optical signal transmitted through the single mode fibre exceeds the power of 200 mW (23 dBm), the dirty connector interfaces may cause severe damage to the fibre. This phenomenon is called fibre core pitting effect.

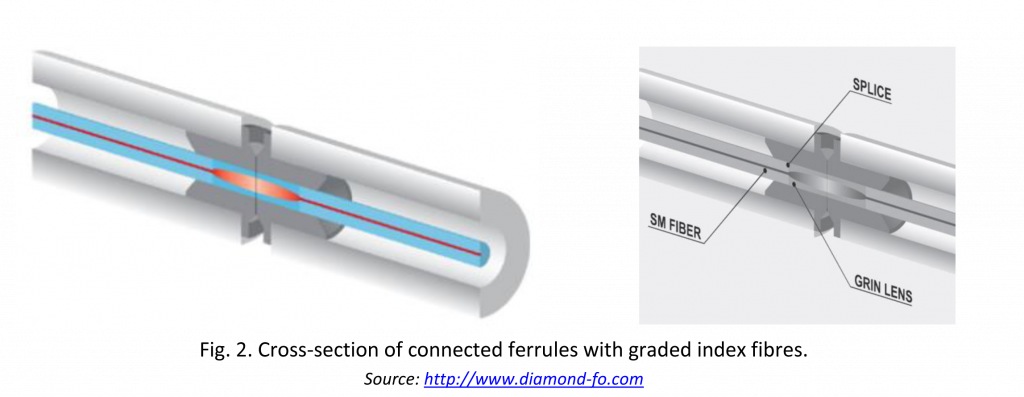

The reason for this are burning particles of dirt that are deposited on fibre core surface. With high power optical transmission even the smallest dust particles, invisible under microscope, burn and damage the fibre. This effect appears due to very high power density on surfaces of mated fibre cores. The power density on the surface of a fibre core with 9 μm diameter transmitting the optical signal with the power of 1000 mW (30 dBm) reaches the value of 16 mW μm2. The natural way to eliminate the problem could be to keep the connectors perfectly clean. This anyway is impossible in practice. The only effective way to eliminate the fibre core pitting effect, when high power optical signals are transmitted, is application of single mode connectors with extended fibre core interface diameter. The technology of extended beam high power fibre interfaces has been developed and implemented by the Swiss company Diamond. The ferrules with built in sections of graded index fibres provide extension of fibre core interface surface from 64 μm2 to 1260 μm2.

FTTH infrastructure within Multi-Dwelling Units

The extended beam transmission provides a significant reduction of power density at fibre interface. This results in lower sensitivity of the connector to dirt. With the transmitted optical power of 1000 mW the power density value at fibre core interface is 0.8 mW/μm2. Silica, the material of the fibre core, melts in result of the heat generated from burning dirt when the power density at fibre core interface reaches the value of 3 mW/μm2.

The following comparison well illustrates how effective the extended beam technology is. The power density on the surface of 9 μm diameter fibre core transmitting the optical power of 250 mW amounts 4 mW/μm2 while the power density on the surface of 40 μm diameter core of a graded index fibre transmitting the optical power of 3 W amounts only 2.4 mW/μm2. It is clear that the transmission of the optical signal with the power of 3 W through the extended beam power connector is save for the fibre in contrast to the transmission of much lower power of 250 mW through 9 μm fibre core diameter. In this case the fibre will be severely damaged, in case it is dirty, as the power density on the fibre core surface exceedes 3 mW/μm2.

The Diamond PS fibre optic power interface solves effectively the heat release problem on polluted fibre cores, however, keeping connectors and adapters clean remains still a key issue when high power optical signals are transmitted.

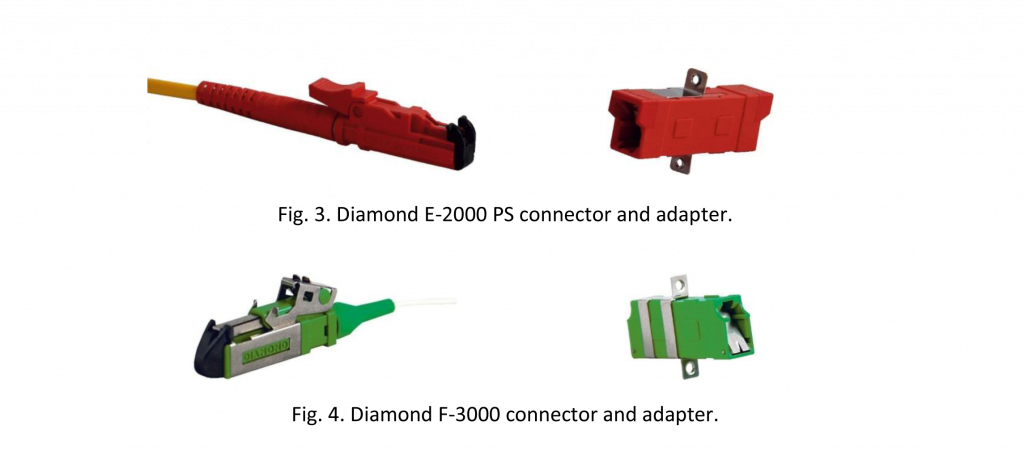

Using Diamond Active Core Alignment technology a very low values of Insertion Loss can be achieved for the PS interfaces by aligning the fibre angle at the ferrule end face. This technology can be applied to most connector interfaces, but due to safety reasons it is suggested to use it with E-2000™ and F-3000™ connector housings which are equipped with integrated metal protection caps and shutters.

Specifications of the PS optical interface:

- 1dB Grade ferrule with diameter tolerance < 0.2μm,

- aktywne centrowanie rdzenia włókna światłowodowego z zawężoną wartością kąta wyjścia światła z czoła ferruli < 0.15°

- niecentryczość < 3,5μm

- powiększona średnica pola modów: < 35μm

- 100% kontrola czoła ferruli

Geometria czoła ferruli:

- czoło ferruli 4° APC

- promień czoła ferruli (10÷20) mm

- apex: 50μm

- położenie włókna (-50÷200) nm (wartość ujemna oznacza podcięcie włókna)

Developed by:

MSc Eng. Tomasz Rogowski

Optomer Development Department

e-mail: t.rogowski@optomer.pl

phone: +48 42 611 01 00 ext. 31

International sales:

e-mail: sales@optomer.pl

phone: +48 42 640 52 15