Fibre optic connectors are the key components of the fibre optic network allowing the transmission of optical signals between optical fibres. The quality of connectors affects the transmission performance of the whole fibre optic network. One of the key connector parameters is the insertion loss also referred to as attenuation.

Insertion loss - a key transmission parameter

Insertion loss is the critical parameter of a fibre optic network that directly affects the quality of the optical signal and transmission distance. High insertion loss leads to the reduction of signal strength, which results in signal distortion, errors and lowered transmission distances. To ensure reliable and effective transmission of the optical signal, it is necessary, among other things, to minimise the insertion loss of fibre optic connectors.

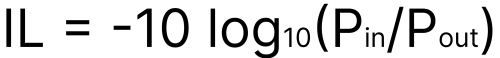

The measure of the optical signal loss in the fibre optic connector is the attenuation called the Insertion Loss (IL). This is the ratio in logarithmic scale, expressed in decibels (dB), of the optical signal power behind the connector to the optical power of the signal before the connector.

where:

IL – Insertion Loss

Pin – optical signal power before the connector

Pout – optical signal power behind the connector

The Most Important Factors Affecting Insertion Loss

Fibre connection eccentricity in the optical fibre interface

Reasons:

– different fibre core diameters of connected fibres

– fibre core to cladding eccentricity

– different ferrule bore dimeters in the fibre optic connector interface

– ferrule bore eccentricity relative to ferrule geometric axis

Optical fibre bending

Fibre optic connectors are equipped with a spring loaded mechanism providing a sufficient pressure of the mated ferrules. When mated the ferrules shift bending the fibres. Fibre bends elevate the attenuation especially within the longer wavelength bands. This phenomenon may have adverse influence on the transmissions using Coarse Wavelength Division Multiplexing (CWDM) and Dense Wavelength Division Multiplexing (DWDM).

Fibre end-face position relative to the ferrule end-face

The excessive fibre undercut can lead to creation of the air gap between mated fibres resulting in high insertion loss and high signal reflection. The excessive extrusion of mated fibres above the ferrule end-face can cause fibre fractures, leading to light leakage into the cladding.

Different parameters of mated optical fibres

The mated optical fibres can differ in core diameters, numerical apertures, and refractive index distributions.

Improper ferrule end-face shape

Non-ideal physical parameters of the ferrule end faces can result in imperfect contact between the connecting fibres, leaving gaps or causing non-planar contact.

Excess of stress on the ferrules

The fiber can cause fractures, leading to light leakage into the cladding.

Ferrule quality

The ferrule bore diameter, its centricity relative to the ferrule geometric axis and the lowest possible ovalities of the ferrule bore and of the ferrule itself play a key role for the centricity of the mated optical fibre cores.

Scratches and cavities on the ferrule end-face

Scratches and cavities cause increased insertion loss, especially when they are numerous and located within or in the close vicinity of the fibre core.

Ferrule end-face contamination

Ferrule end-face contamination is a primary cause of high insertion loss. They can be effectively removed with the use of lint free wipes, isopropyl alcohol, and dedicated fibre optic connector cleaners.

Improper manufacturing processes and the use of inferior components

Lack of manufacturing process management and the use of cheap low quality components result in inconsistent uncontrolled quality.

How to Minimize Insertion Loss of Fiber Optic Connections?

The insertion loss of fibre optic connectors can be minimized by selecting high quality components, controlling production processes, and properly cleaning and inspecting fibre optic ferrule end-faces as well as applying good fibre optic connector installation and maintenance practices.

OPTOMER guarantees the production of high-quality fiber optic connectors thanks to a precisely controlled manufacturing environment equipped with modern, technologically advanced machines, testing and measurement equipment. Every stage of the production process follows rigorous quality procedures, ensuring parameter consistency and the reliability of the final products. A key role is played by a highly qualified team of specialists whose experience and technical expertise enable the continuous improvement of technology and the customization of solutions to meet individual customer needs.

The article was created with the support of experts from OPTOMER’s R&D Department.